JTL Training // Uniform & Distribution Project

THE JTL UNIFORM PROJECT.

JTL came to us with a uniform problem. We got together, got creative and solved it.

First a bit of background - JTL Training are one of the UK’s biggest work-based learning providers supporting over 3500 companies with over 8000 learners. They train more apprentices in the building services engineering sector than anyone else. They’re a big deal.

JTL have a really strong brand identity and an even stronger name in their market. Where they found it tough though was to translate that into their uniform across their UK network of staff and trainees. Add to that actually getting the clothing out to their different centres, and managing who and what people could have, was a logistical headache. So we had some issues to solve here, and after some consultation around what JTL already liked about their uniform, and what they would like too improve on, together we came up with a plan.

This revolutionised the way JTL worked and saved them thousands of hours of internal processing and thousands of pounds of stock holding in their stationery cupboards. The burden was gone and their brand was on point. JTL could focus on what they do best - training people, and we took care of the rest.

HOW WE DID IT.

One step at a time. We worked through the brief and the challenges JTL faced to create an efficient & sustainable solution.

STEP ONE / UNIFY THE UNIFORM.

This sounds like an obvious one, but the first thing we did was to completely standardise the range. This starts with picking the right manufacturer brand. The clothing itself needs to be durable, comfortable, on brand and sustainable long term. We worked through the market and found the perfect mix from leading apparel brands across the UK and Europe.

STEP TWO / RELIEVE THE PRESSURE.

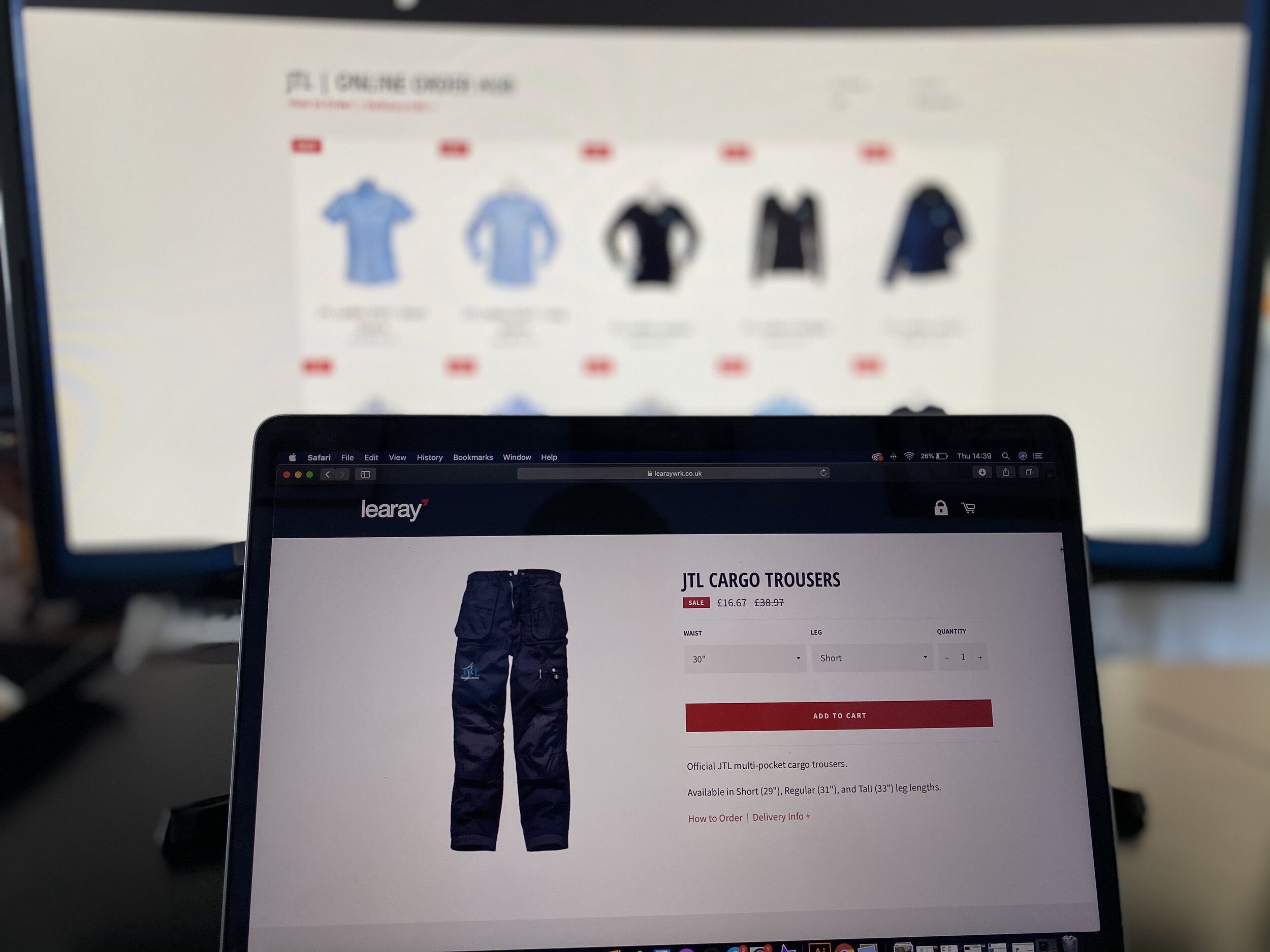

With such a large number of people to cater for and areas of the country to manage, the process of JTL collating orders internally, then placing multiple orders, then holding stock, then figuring out how to get the stock shipped to thousands of addresses across the year was as tough as it sounds. Our solution for this - an online Order Hub. All JTL Uniform in one place and distributed to staff so they could take care of their orders themselves. No more collating and no more placing orders.

STEP THREE / SIMPLIFY THE PROCESS.

The Order Hub took the pressure off of JTL but they still had the issue of logistics. How were they going to get their uniform to the people that needed it? And how could they control what their staff ordered? I mean they had to stay on budget. So we developed the Hub even further to make the experience even simpler. JTL gave every staff member and trainee a “Uniform Allocation”. This was basically what they were allowed to order that JTL would fund. We managed this for them and gave the staff and trainees a more retail experience. They could now place their orders, from their laptops or their phones, we would make sure it was no more than they were allowed (and if they wanted more they could, but they had to pay from their own pockets), and when their order was ready we shipped it straight to their house.